- April 19, 2024

- Metal Buildings

- Carports Advisor

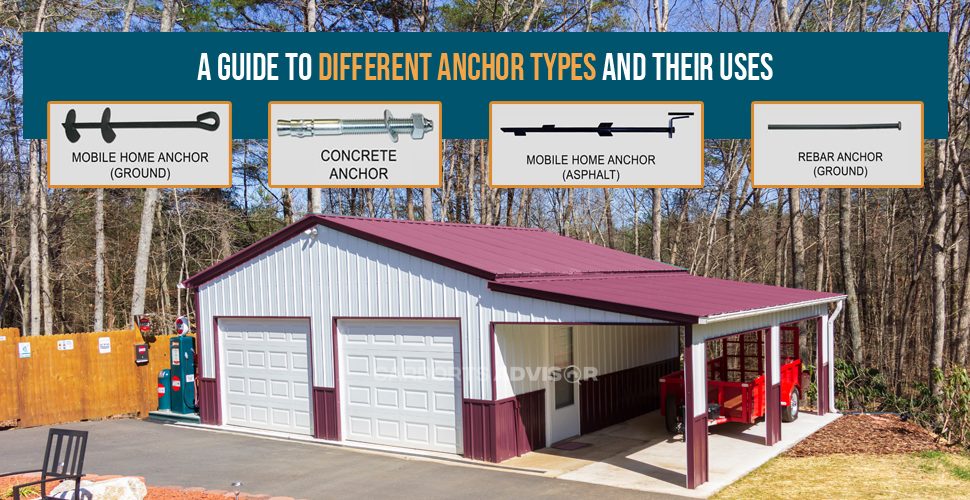

A Guide To Different Anchor Types And Their Uses

Steel buildings are becoming widely popular due to their durability, versatility, and low maintenance. Previously, they were only limited to the industrial sector, but as time passed by, they started to get acknowledged in other sectors, such as agriculture and residential. Almost all steel buildings need a foundation to sit firmly on. The connector between the foundation and the rest of the structure is called an anchor.

If any one is missing, the next thing you know, your structure is air-bone or unstable. So, what are these, how do they function, and what are the different types of anchors? That’s what we will discuss here.

What Is An Anchor?

An anchor is a heavy-duty fastener that connects a metal frame to its foundation. Usually, the anchor is 20 times the diameter of the bolt. The anchor bolt is about 3/8 to 1 inch in diameter and 6 to 30 inches long. However, it can vary for large sizes and areas with extreme weather conditions.

How Does It Work?

The job of the anchor is to pass tension and shear force from the structure toward the ground. Different parts, such as anchor bolts or fasteners, steel plates, and stiffeners, are used to connect the foundation to the steel frame.

A metal carport is one of the most common structures that people generally prefer installing on their lot. And why not? After all, they are multi-purpose, fully open structures that residents can use as a car park, shaded patio, pool shade, or for a family gathering.

How To Anchor A Carport?

You can use any anchors listed below to keep your metal carport firmly grounded. For instance, a mobile home anchor is suitable for a dirt foundation, whereas a concrete anchor is best suited for a concrete slab.

For dirt or gravel foundation: Screw the mobile home anchor to the ground using a pry bar or a suitable power tool. Then, align your base rail and bolt it to the anchor. The mobile home anchor comes in sizes of 30, 36, 40, and 48 inches. You can choose one based on the size of the carport and structural load.

For asphalt foundation: Asphalt base is a mixture of binding material like bitumen and inert material like sand, gravel, and crushed stones. It has a deep greyish to black appearance. Asphalt anchors are used for the asphalt base.

To install, drill the hole, fill it with grout, and then push the anchor into it. Now, you can attach the base rail to the top part of the anchor. This type of anchor comes in sizes such as 16 x 100, 22 x 100, and 22 x 155 (in mm).

Note: The thicker the anchor, the harder it is to pull out. Carports Advisor does not recommend thin anchors for steel carports, as their pull resistance is low.

For concrete foundation: Concrete anchors for metal buildings are used here. These are generally made of galvanized carbon steel or stainless steel. The standard size of concrete (wedge) anchors is ¾, 7/8, 1, and 1 ¼ inches.

To install, drill a hole in the concrete and put an expansion bolt into it. You can use a wrench to tighten it. The anchor must be more than 4 inches away from the edge of the concrete foundation. Now, you can bolt the base rail to the anchor.

Here’s The List Of Metal Building Anchors

Properly anchored metal structures are crucial for the longevity and stability of the metal building. Here are some commonly used anchors.

1. Rebar Anchors

It is used for dirt and gravel bases. These are bolted directly to the base through base rails. However, we don’t recommend them for sandy or loose soil, as they will become dislodged with time. They are also not recommended for windy areas.

Material: Rebar anchors are made of steel and come in different sizes, such as ¼, 5/16, 3/8, ½, 5/8, 7/8, 1, and 1 ¼ inches in diameter. The length should be 16 times its diameter.

Uses: Rebar anchors are mostly used with dirt or gravel type of foundations that are properly leveled.

2. Mobile Home Ground Anchors | Auger Anchors

These are designed to secure the base rail to the dirt/ gravel foundation. The site must be leveled properly before the installation begins. Their wide helix end hooks to the soil and sticks to it, making the entire structure stable. For certified buildings, the anchor must be placed every 25 feet.

Material: Auger anchors are steel bars, ranging in length from 30 inches to 60 inches and width, usually around ¾ inches. The helix and width are about 2 to 4 inches and 1 to 7.5 inches for longer ones.

Uses: Mobile home ground anchors are used with dirt or gravel foundations. Site leveling is a must here.

3. Asphalt Anchors

To keep the building secured, asphalt anchors are designed with screw-like thread or barbs on their shaft to ensure the stability of the metal structure. These anchors are specially designed for asphalt bases and must not be used for concrete or dirt/ gravel.

Material: Asphalt anchors are made of carbon steel or stainless steel. They have a resin – or epoxy-based grout that fixes them to the asphalt base. Generally, the anchors are 6, 10, and 12 inches long, and their diameter is about 7/8, 1, or 1.5 inches.

Uses: Asphalt ground anchors are only used with asphalt foundations. They can’t be used with other types of foundation.

4. Concrete Anchors

To install a concrete anchor, first mark the hole where you need to drill. Then, clean debris from and near that hole. Place a washer on the head of the anchor and secure the nut. Now, place the sill plate and insert the anchor into the hole. Hammer it to secure.

Material: Concrete anchors are made of plated carbon steel, galvanized steel, and stainless steel. The minimum length of a wedge concrete anchor is the sum of (the fastened material thickness + minimum embedment + thickness of the nut and washer).

Uses: Concrete anchors are preferred for concrete slabs or perimeter foundations. Wedge concrete anchors must be installed after the concrete is fully cured. So, waiting for at least 28 days after pouring concrete is best.

Note: Concrete anchors are drilled through the base rail into the pilot hole in the slab.

There are various types of concrete anchors. Some are wedge, sleeve, split drive, stud, and strike anchors. Let’s analyze this in more detail.

Types Of Concrete Anchors

- Light Duty – These are good for holding small weights, mostly up to 50 lbs.

- Medium Duty – These are suitable for holding weights of up to 200 lbs.

- Heavy Duty – These can bear a load of up to 200 lbs.

- Wedge Anchor – Its maximum tensile strength for static load is 4000 psi.

- Drop-in Anchor – Its maximum tensile strength for static load is 4000 psi.

Wedge anchors are best suited for heavy-duty load applications. These are extremely strong, and once inserted, they are nearly impossible to remove. Here, a stainless steel expansion clip that resists corrosion is present. Drop-in anchors are used in construction and manufacturing areas. These can be quickly installed and reduce time & cost by a large amount.

So, Among So Many Different Types Of Anchors, Which One Should You Choose?

Well, it depends on two factors:

- What type of foundation are you pouring?

- How much of a load will there be on the structure?

For instance, a concrete perimeter or slab will require concrete anchors. The number of anchors you need will vary with the size and type of metal building and local building/ zoning laws.

Need Help? Call (336)-914-1654 Today!

Choosing the right anchors for your metal building can be confusing. To ensure maximum stability and longevity, we have an in-house team of experienced professionals who can guide you through the process. We’ll help you choose the most suitable anchor and building style that matches your local codes and is within your budget. Contact the Carports Advisor today for assistance!